Dairies &Dairy Clusters

Serving both the private

and public sectors.

Dairies & Dairy Clusters

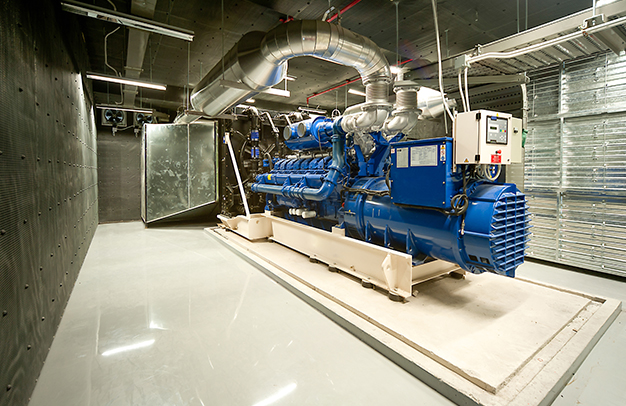

BGE designs and oversees construction of manure digesters and lagoons, as well as networks of collectors to gather gas from multiple dairies (clusters). We design and build centralized generator plants that convert the collected gas into fuel for engine gen-sets and power sales to local utilities. These plants take advantage of state incentives as well as providing environmental benefits (greenhouse gas reduction and odor control).

Services

Engineering

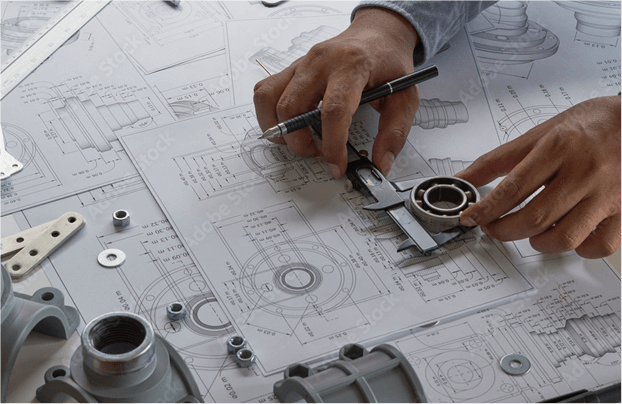

Biogas Engineering staff comprises of industry experts and leaders. We believe in providing simple, elegant and yet cost effective solutions for complex engineering problems. Our staff has expertise in providing turnkey solutions for

Read More- Front-End Engineering Design (FEED)

- Detailed Design

- Balance of Plants

- Landfill Gas (LFG)/Digester Gas(DG) cleanup and treatment system design

- DG/LFG to high BTU facility design

- LFG extraction well design

- LFG collection and control system design

- LFG modeling and projections

- Active and passive methane mitigation (building protection) system design

- Organic food processing facility design

- LFG/DG utilization feasibility studies

- Foundation and building design

- Site planning – civil design (grading and drainage, access roads, utilities)

- Landfill cell and sequencing design

- Hydrological modeling

- Site closure planning and engineering

- Air permitting for LFG control devices

- 2D/3D Designs

Procurement

Read More

- Vendor Selections

- Long Lead item

- Purchasing

- Logistics

- Organic waste processing

- Food waste anaerobic digestion

- Biogas processing and treatment equipment

- Blower and flare assemblies

- Biogas utilization in high BTU application – Pipeline injection, CNG conversion

- Biogas utilization in medium BTU application – direct use, boilers, turbines etc.

- Biogas to energy – Microturbine, engines, Fuel cell etc.

- Biogas cleanup systems – H2S, Siloxane, and VOC

- Compressor system packaging

Construction & Commissioning

Read More

- Field Services

- Construction Management

- Commissioning

- Start-Up

- Construction Quality Assurance (CQA)

Operations & Maintenance

Read More

- High Btu digestor gas pipeline injection

- Medium Btu LFG on-site power generation (sale to utility)

- Medium Btu LFG direct use

- LFG collection and treatment/disposal systems (flares, carbon treatment)

- Integration with existing systems

- Flare gas monitoring

- Permitting

Projects

Lakeside Dairy Cluster

Biogas designed 30 miles pipeline to collect compressed raw biogas from various dairies in the cluster. Biogas also designed a centralized gas upgrading facility which received the gas from the dairies in the cluster and upgraded it to meet So Cal gas pipeline specifications.

Merced Dairy Cluster

Biogas designed 40 miles pipeline to collect compressed raw biogas from various dairies in the cluster. Biogas also designed a centralized gas upgrading facility which received the gas from the dairies in the cluster and upgraded it to meet So Cal gas pipeline specifications.

Keys Dairy Cluster

Biogas designed 35 miles pipeline to collect compressed raw biogas from various dairies in the cluster. Biogas designed and supplied biogas compression and dehydration skids at several dairy facilities. Biogas also designed a centralized gas upgrading facility which received the gas from the dairies in the cluster and upgraded it to meet PG&E pipeline specifications.